Understanding Wheel Balancing

Wheel balancing plays a crucial role in maintaining both the performance and safety of your vehicle. When your wheels are properly balanced, it ensures a smooth and stable driving experience while minimizing potential safety hazards.

Importance of Wheel Balancing

Properly balanced wheels prevent vibrations that can affect the overall comfort of your ride and potentially lead to discomfort for passengers. Additionally, balanced wheels help to distribute the weight evenly across all tyres, reducing stress on individual components and promoting longer tyre life.

Effects of Unbalanced Wheels

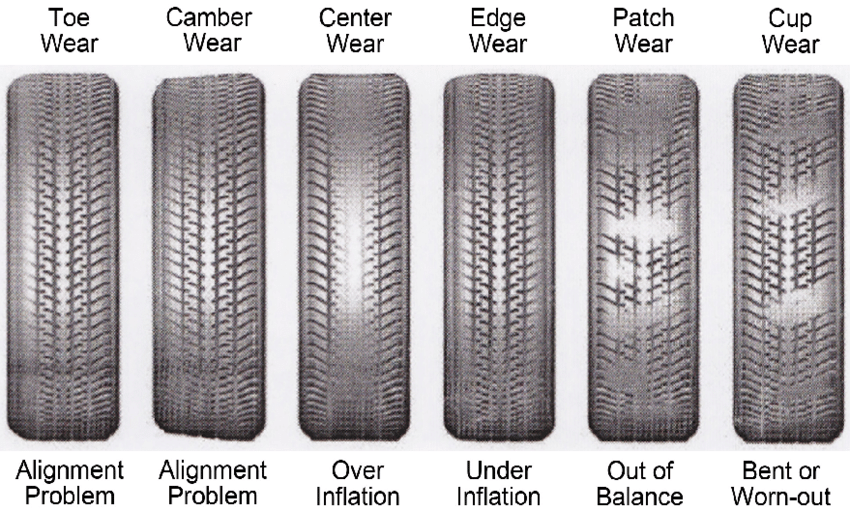

Unbalanced wheels can result in various issues such as vibrations felt through the steering wheel or vehicle chassis, especially at higher speeds. Moreover, unbalanced wheels can cause uneven tyre wear, leading to premature tyre replacement and additional expenses. In severe cases, unbalanced wheels may contribute to safety hazards, affecting vehicle stability and control.

Role of Wheel Balancers

Wheel balancers are essential tools used by automotive technicians to identify and correct imbalances in wheels. By accurately measuring tyre and wheel weight distribution, wheel balancers can pinpoint areas of imbalance and recommend corrective measures such as adding or removing wheel weights. This process ensures that each wheel rotates smoothly and evenly, promoting optimal vehicle performance and safety on the road.

Frequency of Wheel Balancing

Recommendations Based on Driving Habits and Road Conditions

Determining how often to balance your wheels depends on various factors, including your driving habits and the conditions of the roads you frequent. Here are some recommendations to consider:

- Kilometres: Aim to balance your wheels every 8,000 to 10,000 kilometers or during routine tyre rotations to maintain optimal balance.

- Driving Speed: High-speed driving can accelerate tyre wear and imbalance issues. If you frequently drive at highway speeds, consider balancing your wheels more frequently to ensure smooth performance.

- Road Quality: Rough or uneven road surfaces can exacerbate wheel imbalance problems. If you regularly encounter potholes, debris, or poorly maintained roads, you may need to balance your wheels more often to prevent premature wear.

Consult Manufacturer Recommendations

Always refer to your vehicle manufacturer’s recommendations for specific guidance on wheel balancing intervals. These guidelines take into account your vehicle’s make, model, and specifications, providing tailored advice for optimal maintenance. Additionally, consider scheduling regular maintenance appointments with a trusted auto service provider. Professional technicians can assess your vehicle’s condition and recommend appropriate maintenance schedules, including wheel balancing, to ensure safe and efficient operation on the road.

Benefits of Balanced Wheels

Improved Ride Comfort and Handling

Balanced wheels result in a smoother and more comfortable ride by minimizing vibrations and jolts transmitted from the road to the vehicle. This improved comfort enhances the overall driving experience, making long journeys more enjoyable.

Enhanced Tyre Longevity and Fuel Efficiency

Properly balanced wheels promote even tyre wear, extending the lifespan of your tyres and optimizing fuel efficiency. By reducing uneven tread wear, balanced wheels help you get the most out of your tyre investment while also improving fuel economy.

Increased Vehicle Stability and Steering Precision

Balanced wheels contribute to vehicle stability and steering precision by ensuring uniform weight distribution across all tyres. This balance enhances the vehicle’s handling characteristics, making it easier to maintain control and manoeuvre safely, especially at higher speeds or in challenging driving conditions.

Prevention of Premature Tyre Wear and Suspension Damage

Balanced wheels prevent premature tyre wear by eliminating excessive stress on specific areas of the tyre tread. This balanced distribution of weight reduces the risk of irregular tread wear patterns, which can lead to premature tyre replacement and potential suspension damage. By maintaining proper wheel balance, you can extend the life of your tyres and avoid costly repairs down the road.

Conclusion and Recommendations

Selling Wheel Balancing Services and Nitrogen Tire Inflation

Now that you understand the importance of wheel balancing and its significant benefits for vehicle performance and safety, let’s discuss how you can effectively sell wheel balancing services to your customers, along with the idea of nitrogen tire inflation.

Educate Your Customers

Start by educating your customers about the importance of wheel balancing and its impact on their driving experience. Explain how unbalanced wheels can lead to vibrations, uneven tire wear, and safety risks, and highlight the benefits of regular wheel balancing for smoother rides and longer tire life. Additionally, introduce the concept of nitrogen tire inflation and its advantages over traditional air filling methods, such as improved tire pressure retention and enhanced fuel efficiency.

Offer Value-Added Services

Consider offering value-added services along with wheel balancing, such as nitrogen tire inflation. By providing comprehensive maintenance solutions, including nitrogen tire inflation, you can address all aspects of your customers’ vehicle care needs and provide them with superior performance and safety benefits.

Showcase Professional Expertise

Emphasize your professional expertise and experience in using high-quality wheel balancing equipment and nitrogen generating machines. Highlight your certified technicians’ skills and knowledge in performing accurate wheel balancing and nitrogen tire inflation, ensuring optimal results for your customers’ vehicles.

Provide Convenient Options

Make it easy for your customers to schedule wheel balancing and nitrogen tire inflation appointments by offering flexible scheduling options and convenient service hours. Consider implementing online booking systems or mobile service units to enhance convenience and accessibility for your customers.

Promote Customer Satisfaction

Above all, prioritize customer satisfaction by delivering exceptional service and personalized attention to each customer. Listen to their concerns, address their questions, and go the extra mile to exceed their expectations. Happy customers are more likely to return for future services and refer others to your business, helping you build a loyal customer base and drive business growth.

By implementing these strategies and introducing the idea of nitrogen tire inflation, you can effectively sell wheel balancing services and nitrogen tire inflation to your customers and position your business as a trusted provider of quality automotive maintenance solutions. Remember, investing in wheel balancing and nitrogen tire inflation today can lead to happier customers, safer roads, and long-term business success.